고정 헤더 영역

상세 컨텐츠

본문

1There is a problem with the modern diesel engines (and with the other engines) that feed units which inject fuel to combustion chamber are become dirty with the time. This can influence negatively on the engine running and on its start. In this article there will be description of how to deal with injectors Common Rail Bosch (as well you can read article about ). In my case the engine running has not changed significantly but the engine’s start has become to experience difficulties. I could not understand what was going on. In case I pushed my car the engine started very well.

But this was almost impossible with starter unless liquid «Start fluid» on the base of ester could help anyhow. The start was when revolves was increasing within 5-7 sec and its were close to 800 rpm. The car’s operational kilometers was 100K. This was high time I began to change injectors.As far as I did not know what was wrong I decided to go to diagnostics at service station.

The servicemen told me that «the pressure in fuel Common Rail grew very slowly». And there are two reasons are possible: diesel high pressure fuel pump has been frayed and it flushed weakly or back-pressure valves in injectors did not hold fuel and fuel leaked through this one. Which is to say that injectors pour off fuel to by-pass channel. After deep thinking it was decided to start with injectors' cleaning, as far as in any case there was time to change its by the book. If its break I will buy new ones.

If injectors resume working I will know for the future that their resource is more that 100K operational kilometers. For this time being the price for 1 injector was approximately 400 USD.

This was the cheapest one which I had found. There are 3 types of this injector «X», «Y» and «Z». As manufacturer claims that it is impossible to insert in engine all 3 cheap pieces, its must be in combination with others. Not the cheapest injector’s cost was 1K USD. I have not any distinct idea why prices differs a lot however I think that the ecology is the main point.Prior to startingI overhauled injectors without preparation as far as I had done this operation not for the first or the second time.

Before the first time of injectors' overhaul I prepared very well theoretically, I studied its working actions, operation principles and control system of injectors. This was difficult process to understand how all this works and I spent two days studying theory. Eventually I cottoned on.

Briefly I will tell how its work.Initial conditions: the injector is closed, the fuel’s working pressure in input approximately 300 bars or more. Injector’s opening: voltage applies to the solenoid coil, back-electromagnetic valve is being opened. The ball which closes the output orifice is going up and fuel starts discharging to back channel. The fuel pressure in control chamber is going down. Before this the same pressure influenced on the all details of injector meaning that on the needle from bottom and on increaser from the top as well. Therefore the fuel pressure difference from below and in control chamber begins moving needle and increaser to the top and injector’s atomizing holes open. When control voltage removes the back-valve closes and pressure in control chamber increases.

After this due to internal pressure the needle of nozzle is pressed to the support saddle. And in conditions of working pressure absence the needle is pressed to the support saddle with the spring.Demonstrative Movie «How does Common Rail Injector Work»Getting to the workFirst of all.Dismantling of injectors Common RailWe twist off solenoid and see inside spring and ring. We hold to injector’s body with wrench (12) but you may use instrument the most comfortable for you. The most thing is that you must hold injector strongly, pliers or something else are not the right choice.

Common Rail Injector Problems

But with pliers we twist off metal screw which holds the solenoid (as indicated on the photo below). Please note that I could not twist off screw with pliers, just only gas wrench helped me to do this. However when I dismantled injectors for the first time everything was twisted off with the help of pliers.

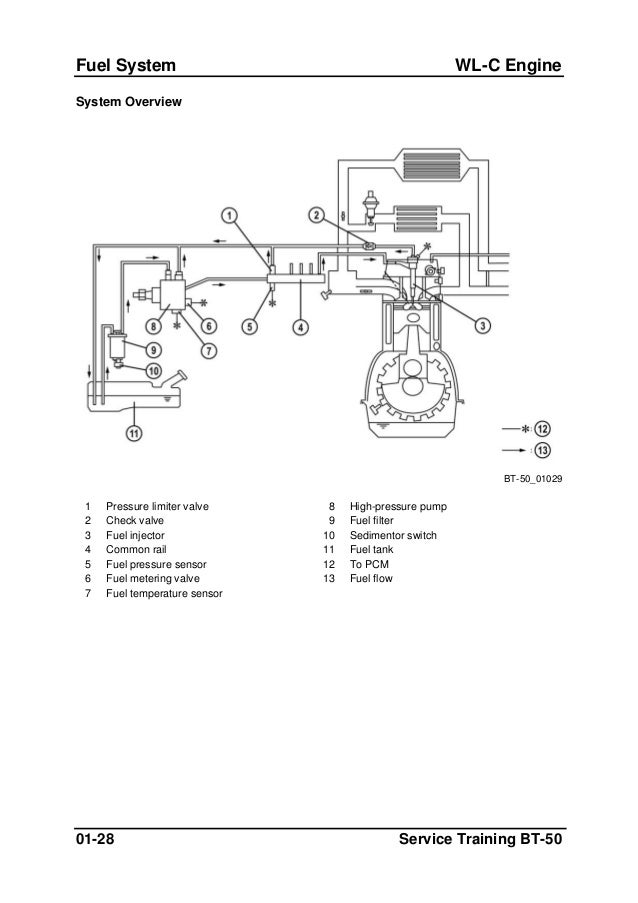

Common rail injection: advanced technology for diesel enginesBosch launched the first common rail system in 1997. The system is named after the shared high-pressure reservoir (common rail) that supplies all the cylinders with fuel. With conventional diesel injection systems, the fuel pressure has to be generated individually for each injection. With the common rail system, however, pressure generation and injection are separate, meaning that the fuel is constantly available at the required pressure for injection.

Mode of operationWith conventional diesel injection systems, the fuel pressure has to be generated individually for each injection. With the common rail system, however, pressure generation and injection are separate, meaning that the fuel is constantly available at the required pressure for injection.

Bosch Common Rail Injectors

Pressure generation takes place in the high-pressure pump. The pump compresses the fuel and feeds it via a high-pressure pipe to the inlet of the rail, which acts as a shared high-pressure reservoir for all injectors – hence the name 'common rail'. From there, the fuel is distributed to the individual injectors, which inject it into the cylinder's combustion chamber.

The injector in a common rail system consists of the nozzle, an actuator for Piezo injectors or a solenoid valve for solenoid valve injectors, as well as hydraulic and electrical connections for actuation of the nozzle needle.It is installed in each engine cylinder and connected to the rail via a short high-pressure pipe. The injector is controlled by the Electronic Diesel Control (EDC). This ensures that the nozzle needle is opened or closed by the actuator, be it solenoid valve or Piezo.

Injectors with Piezo actuators are somewhat narrower and operate at a particularly low noise level. Both variants demonstrate similarly short switching times and enable pre-injection, main injection and secondary injection to ensure clean and efficient fuel combustion at every operating point.